With OCTG, it’s essential to ensure that the right materials are available at the right time, in the right place, and at the right cost. To do this, you need to have a solid understanding of supply chain management, a skill set that involves the coordination of all activities involved in the production and delivery of goods or services, from the initial sourcing of raw materials to the delivery of the final product to the end consumer.

The importance of supply chain management in OCTG cannot be overstated. In a highly competitive market with fluctuating demand, efficient supply chain management can give you a significant edge in terms of cost-effectiveness and responsiveness to customer needs. It also helps to reduce risks such as production delays, inventory shortages, and quality issues, which can have serious implications for the overall success of a project if not properly mitigated.

Top Strategies

1. Overcome supply gaps

Shortages of products and services can cause businesses to experience delays, loss of revenue and reputational damage. They can also have a wider social impact if the supply gap relates to an essential commodity. Developing contingency and risk mitigation plans helps you prepare for potential supply chain disruptions.

This can include diversifying your supplier base to ensure you have multiple suppliers for critical items, researching backup manufacturing sites and implementing an inventory management system. It’s also crucial to develop and refine your demand forecasting, which involves studying historical data and market trends to better inform your forecasts.

This will enable you to adjust production schedules and inventory levels accordingly so that you are better prepared for supply gaps.

2. Reduce inefficiencies and make use of modern technology

As technological solutions become more and more advanced, there is less need for employees to be directly involved in tasks relating to data interpretation, inventory monitoring or order preparation. Instead, these activities can be automated, enabling employees to put their time towards more specialised tasks.

The use of modern technology can improve the accuracy of data and provide heightened supply chain visibility, leading to better-informed decision-making and enabling you to identify long-term trends and potential supply gaps on the horizon.

The overall effect of this is that companies that implement automation attain a higher level of agility, meaning they are equipped to respond faster to changes in demand and supply as they arise, while also reducing costs by eliminating inefficiencies.

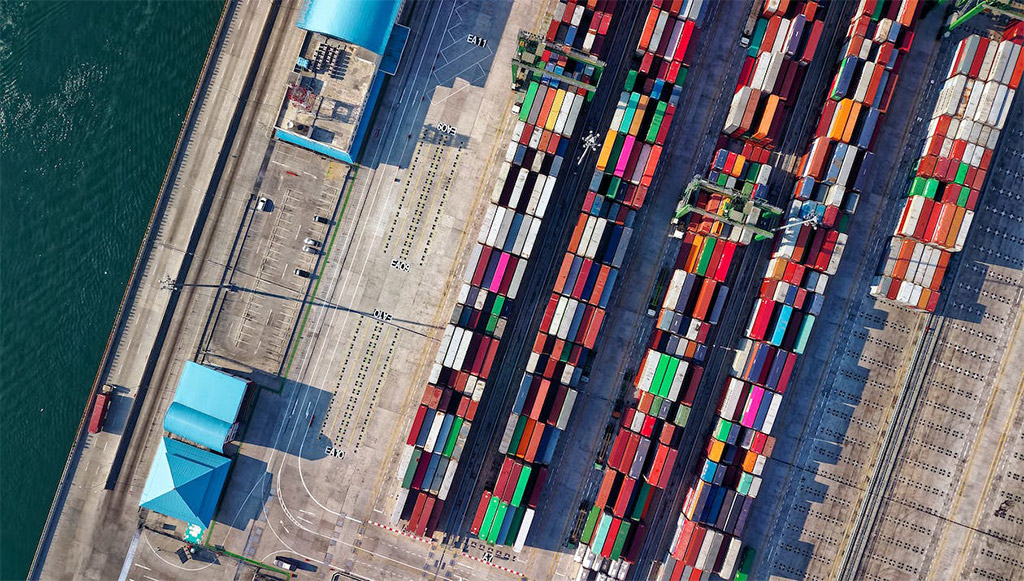

3. Manage shipping and transportation costs

Transporting goods on an ad-hoc basis or neglecting to optimise your transportation processes to prioritise cost-effectiveness is a missed opportunity to reduce your expenditure. Instead, there are a number of factors you should consider before commencing transportation, including the size and weight of the products, the distance to be covered, the transportation options available and the urgency of the delivery.

With these factors in mind, research the cost profiles of each option, including transportation fees, fuel and labour costs, contingencies for repairs or maintenance, insurance, and so on.

Once you are properly informed about your transportation and shipping options, you can start making more strategic decisions to minimise costs. Examples include choosing to consolidate smaller shipments into a single larger one, using advanced analytics to generate recommendations on transportation options, negotiating rates with carriers and logistics providers, and using automation to reduce the amount of manual work needed to process shipments.

4. Closely monitor and reduce inventory loss

Loss or damage sustained to your inventory is a sunk cost that is easy to minimise with appropriate oversight procedures. Monitoring inventory not only reduces instances of loss or damage but also enables you to identify trends and respond to them accordingly.

There are a number of technological solutions that can give you better control of your inventory, including the implementation of an inventory management system, especially one that can integrate with your relevant Enterprise Resource Planning (ERP) systems to improve visibility and enable proactive and informed decision-making.

Whether it’s through an inventory management system or any other method, it’s also important to monitor and analyse inventory metrics, such as turnover and obsolete inventory, and to establish inventory management best practices like cycle counting and monitoring demand trends. Along with improving warehouse operations and administering training to employees responsible for storing and handling inventory, investing in these processes will help to both safeguard your inventory and increase your visibility over it.

5. Turn your excess stock into capital

Holding onto surplus inventory is often a drain on resources, taking up costly storage space that could be put to better use. Stockpiling inventory will also prevent you from realising its financial value. Selling your excess stock at fair market value is one way to resolve both of these problems at once.

In the case of excess tubulars, the Pipesales global marketplace is a great place to sell your inventory in a safe and secure manner, and you’ll be supported through the whole process by your local Marubeni-Itochu Steel Inc agent.

Additionally, Marubeni Itochu Tubulars’ leading cloud-based digital platform Tubestream employs the latest technology to monitor and manage your inventory. Tubestream enables accurate and efficient operations by facilitating all aspects of your tubular service, from inventory procurement to surplus management.

Learn more about Tubestream here and start increasing the efficiency of your inventory processes today.